All types of concrete for your job

Learn about some of the concrete we provide:

PUMPED

Used for the majority of construction jobs, its mix is designed to be used with concrete pumps.

Applications

• Construction jobs in general;

• Jobs in hard to reach areas;

• Deals with the need to overcome long distances or great heights.

Benefits

• Easy placement;

• Faster pouring speeds;

• Lower labor costs on delivery.

CONVENTIONAL

It is normally used when there are obstacles to concrete conveyance by pump. In this case, conveyance is done by wheelbarrows, cranes and tower cranes.

Applications

• Building construction in general.

Benefits

• Lower cost when compared to concrete mixed on-site;

• Eliminates waste of material on site.

CONCRETE SLABS

The main requirements of this type of concrete are durability and surface finish. Its usual compressive strength is 30.0 MPa.

Applications

• Industrial floors;

• Gas station floors.

Benefits

• Easy placement;

• High productivity.

SELF-COMPACTING

This is the concrete of the future, a concrete of high plasticity. Thanks to its rheology, it can fit in any type of mold, and fill voids in hard to access places.

Applications

• Special foundations such as continuous flight augurs propellers and diaphragm walls;

• Highly reinforced elements;

• Concrete walls.

Benefits

• Extended lifetime;

• Easy placement, as it does not require the use of vibrators;

• Higher pouring productivity.

FIBER REINFORCED

It is usually made by adding fibers to the concrete. The most used types of fibers are: polypropylene, steel, glass and synthetic.

Applications

• Industrial and warehouse floors;

• Airport runways;

• Concrete walls.

Benefits

• Replaces steel frames;

• Greater resistance to traction;

• Curbs the effects of cracking.

PAVEMENTS

The main requirement for this concrete is tensile strength in flexion and strength in surface wearing. This type of concrete is easy to pour and place.

Applications

• Highways and streets;

• Surfacing of bridges and overpasses;

• Airport runways.

Benefits

• Greater durability;

• Lower maintenance cost;

• Cost savings in street lighting.

LOW-PERMEABILITY

This is a kind of concrete with a low water-cement ratio, in accordance with the technical specifications. It is mixed with an appropriate cement, such as Portland blast furnace or pozzolans.

Applications

• Hydraulic works;

• Water and sewage treatment plants;

• Anti-flotation slabs;

• Dams.

Benefits

• Extended lifetime.

• Lower maintenance costs.

HIGH-PERFORMANCE

Prepared with mineral admixtures such as silica fume, metakaolin and special admixtures. They have excellent properties with high compressive strength and high durability.

Applications

• Complex building structures;

• Restoration;

• Hydraulic works;

• Pre-stressed structures.

Benefits

• Extended lifetime and greater durability;

• Cost saving;

• Better use of the areas available for constructions;

• Better adhesion between concrete and steel.

EXTRUDED

It is a type of concrete with a drier consistency, specified by cement content, used for very specific jobs.

Applications

• Curbs and gutters;

• Jersey barriers.

Benefits

• High productivity.

ICE-COOLED

It’s a type of concrete in which some or all of the water of the mix is replaced by ice. Another way to cool the concrete is through the use of liquid nitrogen. In both cases, the cooling is done in order to reduce thermal contraction that may develop within.

Applications

• Large volume parts, such as bases or foundation blocs;

• Dams.

Benefits

• Eliminates thermal cracking;

• Improves concrete consistency maintenance;

• Allows for greater compressive strength.

SHOTCRETE

Shotcrete is a type of concrete that is applied, with a special equipment, into a surface, to which it must adhere. There are two methods of application: the dry process and the wet process.

Applications

• Structural strengthening;

• Tunnel linings;

• Retaining walls for slopes and hillsides.

Benefits

• It does not require formwork;

• Fast application;

• Rapid hardening.

LIGHTWEIGHT

The particular density of this concrete is lower than 2000 Kg/ m³. The most common types are foamed cellular concrete, obtained by the use of special admixtures, and concretes with light aggregates, such as Styrofoam pearls, expanded-clay, EVA and vermiculite.

Applications

• Sealing elements (walls, panels, and partitions);

• Filling and leveling of slabs and flooring.

Benefits

• Reduced dead load;

• Thermoacoustic insulation.

INTEGRALLY COLORED

It is characterized by the addition of special pigments to the concrete. The most popular colors are: green, yellow, blue, red, brown and black.

Applications

• Exposed concrete structures;

• Facades;

• Sports courts;

• Sidewalks;

• Monuments;

• Bike paths.

Benefits

• Delimiting specific areas;

• Eliminates the costs of coating;

• Avoids painting maintenance costs.

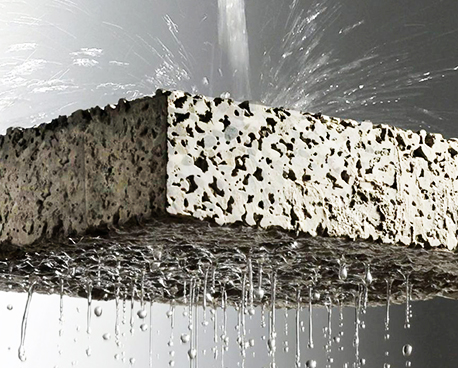

PERMEABLE

It has a porous structure due to the non-use of small aggregates, providing a high water percolation through its interconnected voids.

Applications

• Drains;

• Gutters;

• Parking lots;

• Fillings.

Benefits

• High permeability;

• Runoff of rainwater.

ROLLER COMPACTED

Concrete of a drier consistency, its placement is made in layers that are compacted by vibratory rollers that go over it several times, until getting to the right degree of compaction.

Applications

• Subbases for urban and highway pavements;

• Subbases for airport runways;

• Dams.

Benefits

• High productivity;

• Low cost.

HEAVYWEIGHT

The particular density of this concrete is greater than 2800 Kg/ m³. It is obtained by replacing conventional aggregates with special aggregates of hematite, barite and, less commonly, with steel spheres with diameters up to 20mm.

Applications

• Counterweight (for example, in gas pipelines);

• Radiation shielding (X-ray or gamma cameras, walls of atomic reactors);

• Anti-flotation slabs.

Benefits

• High dead weight;

• Reduction in the amount of parts used as ballast, counterweight and armor;

• Replacement of lead panels;

• Radioactive insulator.

Ask our Technological Laboratory about other types of concrete: ctt1@polimix.com.br

Our tips for concrete pouring

Get Tips to learn how to improve your concrete pouring